directory BFC Industries

BUSINESS-ALU MASUE (BAM)

Last update : 05/02/2026Coordinates

Primary address : 11 route de Chamvres89300 JOIGNY Secondary address : ZI Phone : 03 86 62 14 54 E-Mail : commercial@icm-bam.fr

General Information

- Company name : BUSINESS-ALU MASUE (BAM)

- NAF code : 2453Z

- Juridical status : SAS

- Date of creation : 1966

- Social capital : 250 000€

- Workforce : 65

- Siret : 506 650 142 00017

- Turnover (EXCL. VAT) : 12 000 000€

- Turnover Export (EXCL. VAT) : 8 000 000€

- Customer references : Hermès, Valeo, Virax, Hutchinson, Outils Wolf, defta, ZF, Frisquet, alfalaval

- Languages : Allemand, Anglais, Français

- Other locations in France : HADOUX, 9 rue Gutenberg 51100 REIMS

Manager(s)

-

M. Bruno JANVIER

President -

M. Benjamin JANVIER

-

M. Mathieu SOUMIREU

Administrative and financial director

Know-how(s)

- Assembly of sub-assemblies / Electrical / electronic assemblies

- Assembly of chronometric sub-assemblies

- Assembly of sub-assemblies, electromechanical, mechatronic, mechanical assemblies with a volume < 0,1 cm3

- Assembly of sub-assemblies, electromechanical, mechatronic, mechanical assemblies with a volume < 1cm3

- Assembly of sub-assemblies, electromechanical, mechatronic, mechanical assemblies with a volume < 5cm3

- Assembly of sub-assemblies, electromechanical, mechatronic, mechanical assemblies with a volume > 1000 cm3

- Assembly of sub-assemblies, electromechanical, mechatronic, mechanical assemblies with a volume > 50cm3

- Assembly of sub-assemblies, electromechanical, mechatronic, mechanical assemblies with a volume > 500cm3

- Assembly of sub-assemblies, electromechanical, mechatronic, mechanical assemblies with a volume > 5000 cm3

- Assembly of sub-assemblies, electromechanical, mechatronic, mechanical assemblies with a volume > 5cm3

- Robotic design office

- Mechanical engineering office

- Industrial lighting design and manufacturing

- Design and manufacture of press tooling

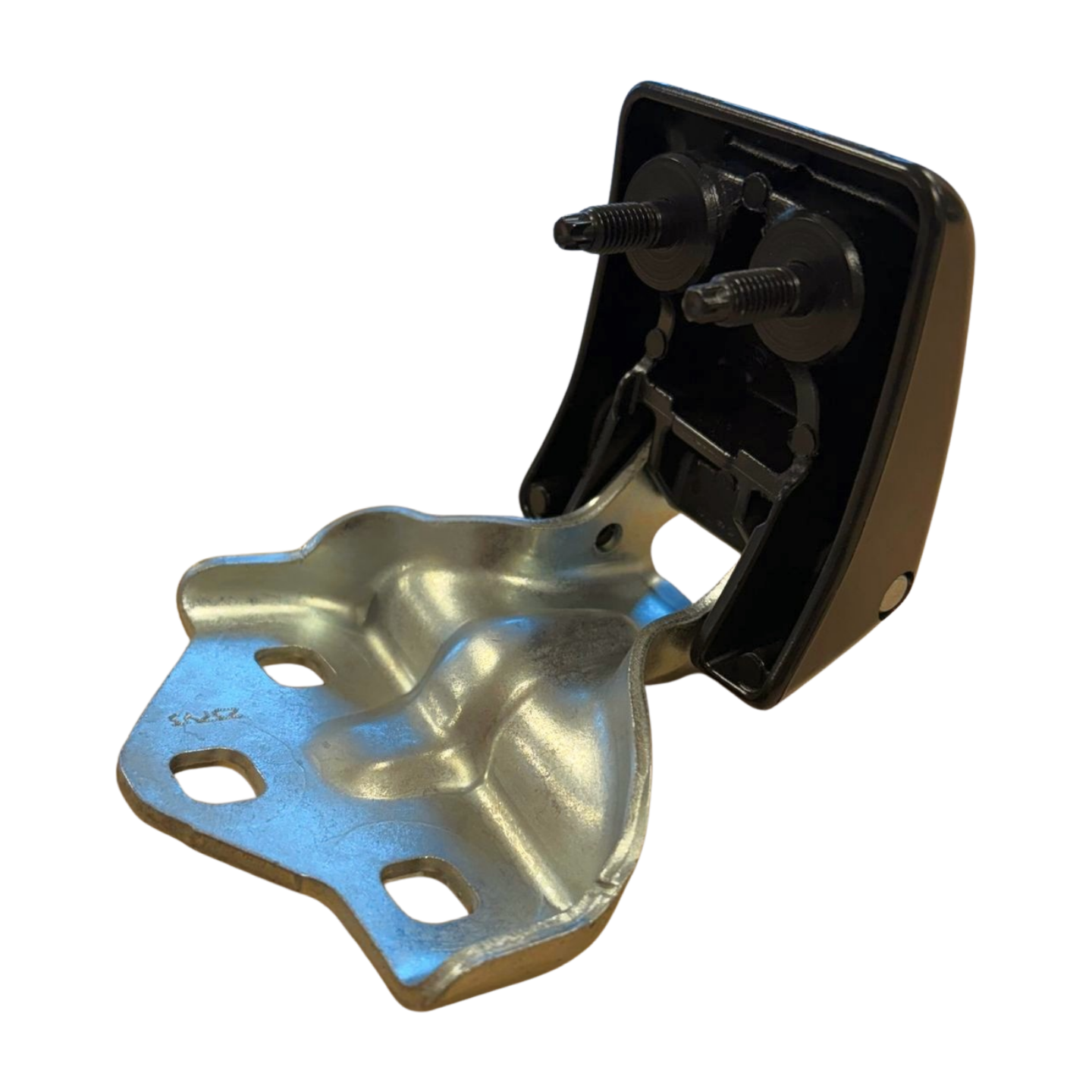

- Design and manufacture of automotive products

- Dimensional control

- Contrôle non destructif par tomographie

- Degreasing / Cleaning / Washing

- Tribo-finishing deburring

- Manufacture of foundry tools

- Manufacture of press tools

- Manufacturing of tools for plastic injection

- Aluminium alloy casting

- Fonderie alliage spéciaux

- Fonderie aluminium

- Other metals foundry

- Fonderie coquille

- Die casting

- Fonderie sous pression

- Fonderie V-process et sable

- Industrial furnaces for foundry and heat treatments

- Horizontal milling

- Serial milling

- Vertical milling

- Engraving

- Shot blasting

- Injection aluminium sous pression

- Laser (engraving and marking)

- V Process

- Industrial paint

- Prototypes (design)

- Prototypes (small series manufacturing)

- Spectrometer (analysis, measurement, control)

- Overmolding

- Camera control system

- Pad printing

- High-speed machining / 3 axis /large series (>10 000 parts) < 350 cm3

- High-speed machining / 4 axis / medium series (from 1001 to 10 000 parts) < 350 cm3

- High-speed machining / 4 axis /large series (>10 000 parts) < 350 cm3

- High-speed machining / 5 axis /small series (from 10 to 1000 parts) < 350 cm3

Destination industries

- Aeronautics

- Aerospace

- Layout/Furnishing

- Agricultural field

- Automotive

- Household appliances

- Energy

- Mobilier urbain

- Sport

- Transportation sector

Technical information

MATERIALS WORKED ON

- Aluminium

MACHINERY AND EQUIPMENT

- 18 presses d'injection de 50 T à 1 600 T

- 11 centres d'usinage 3 et 5 axes

- Chantiers V Process

- 8 unités coquilles

- Unités de noyautage

- Machines de contrôle 3D et rayon X scan

- Tribofinition et grenaillage

- Salle grise

Certifications

- IATF 16949

- ISO 9001

Download our technical and sales documentation

Observations

Business Alu Masué (BAM) is a recognized industrial player in the Bourgogne–Franche-Comté region, known for its expertise in high-pressure aluminum die casting and precision machining. We support our clients from the co-design phase to develop reliable, high-performance parts perfectly tailored to their needs. With a modern industrial facility featuring 20 presses and advanced inspection capabilities (X-ray, tomography, CMM), we control every stage of production with rigor and consistency. Certified to IATF 16949, we place quality, responsiveness and technical excellence at the heart of our approach. Our integrated organization, commitment to service and culture of innovation enable us to deliver complete and durable industrial solutions for the most demanding sectors, including automotive, energy and household appliances

Photos

in the next edition?